In the world of industrial automation and control systems, communication protocols play an essential role in facilitating data exchange between various instruments and devices. These protocols ensure that devices can communicate efficiently, reliably, and securely, making it possible to monitor, control, and optimize processes. This article explores the most commonly used communication protocols in instrumentation, explaining their key characteristics and applications.

1. Modbus Communication Protocol

Modbus is one of the most widely used communication protocols in industrial environments. It was developed in 1979 by Modicon (now part of Schneider Electric) and remains an open, simple, and reliable protocol for data transfer. Modbus typically operates over serial communication (RS-232 or RS-485) and supports a master/slave architecture. This makes it ideal for applications such as programmable logic controllers (PLCs) communicating with sensors, actuators, or other industrial devices. Its simplicity and robustness have ensured that Modbus is still prevalent in process automation and building management systems.

Key features:

- Serial Communication: RS-232 or RS-485.

- Master/Slave Configuration: One device (the master) initiates communication with other devices (the slaves).

- Open and Free: No licensing costs for implementation.

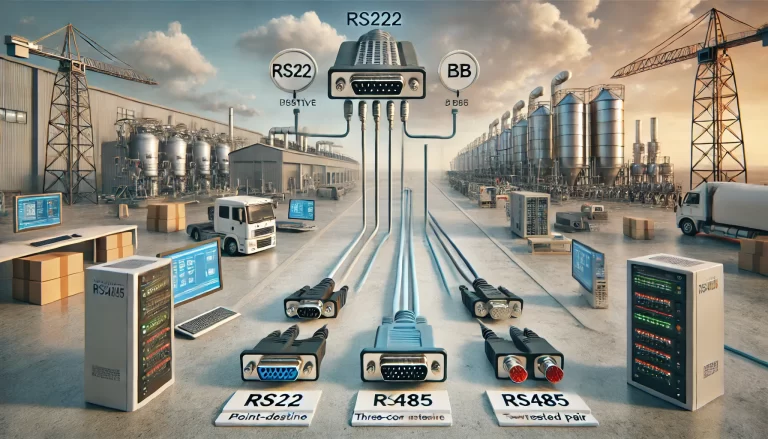

2. RS-232 Communication Protocol

RS-232 (Recommended Standard 232) is an early standard for serial communication introduced in the 1960s. Although it is one of the oldest protocols, RS-232 remains popular for short-distance point-to-point communication between devices such as computers and peripherals, laboratory instruments, and industrial controllers. However, its limited transmission distance (typically less than 15 meters) and low communication speed make it more suitable for simple, low-speed data transfer applications.

Key features:

- Short Distance: Maximum 15 meters.

- Low Baud Rate: Limited to lower speeds (up to 115 kbps).

- Point-to-Point: Typically used for one-to-one device communication.

3. RS-485 Communication Protocol

RS-485 is a robust serial communication standard, and unlike RS-232, it supports multiple devices on the same communication bus, making it ideal for industrial environments. It allows for longer transmission distances (up to 1200 meters) and higher data transfer rates. RS-485 supports half-duplex communication, where devices can either send or receive data at any given time. It’s often used for connecting sensors, actuators, or other instrumentation over longer distances in harsh environments.

Key features:

- Multi-Device Communication: Supports up to 32 devices on the same bus.

- Longer Distance: Up to 1200 meters.

- Robust and Noise-Resistant: Suitable for industrial environments.

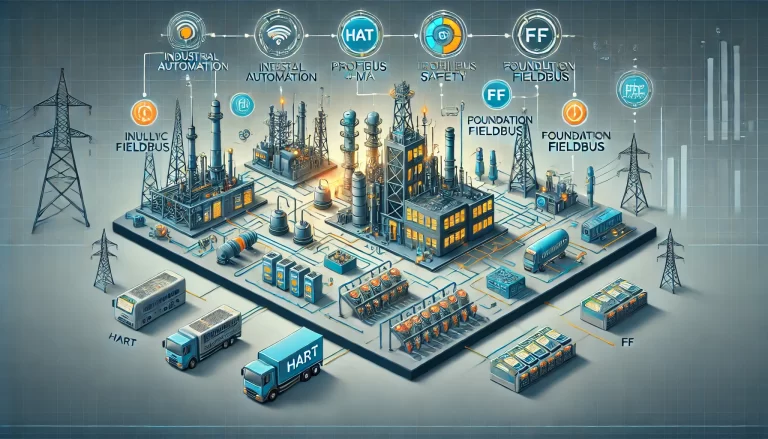

4. HART Communication Protocol

HART (Highway Addressable Remote Transducer) is a hybrid communication protocol that allows both analog and digital communication over the same wires. It is extensively used in process control systems, where existing 4-20 mA analog wiring is leveraged for digital communication. HART enables two-way communication with field devices such as sensors and actuators, allowing for configuration, diagnostics, and data acquisition without interrupting the primary process.

Key features:

- Analog and Digital Hybrid: Operates on existing 4-20 mA loops.

- Two-Way Communication: Real-time data exchange between control systems and field devices.

- Non-Intrusive: Enables communication without disrupting the analog signal.

5. MPI (Multi-Point Interface)

MPI is a communication protocol developed by Siemens for its S7 series of programmable logic controllers (PLCs). It enables communication between several PLCs, human-machine interfaces (HMIs), and other Siemens devices. MPI is suitable for small to medium-sized automation systems, where several devices need to exchange data for control and monitoring purposes.

Key features:

- Siemens-Specific: Primarily used with Siemens automation systems.

- Multi-Point Communication: Multiple devices can communicate on the same bus.

- Ideal for Small Systems: Often used in compact automation setups.

6. Serial Communication

Serial communication is a broad term for protocols like RS-232, RS-485, and others that transmit data one bit at a time. This method is slower than parallel communication but requires fewer wires, making it cheaper and simpler to implement. Serial communication is common in industrial and embedded systems where simple, low-cost data transfer is sufficient.

Key features:

- Low-Cost: Requires fewer resources and is easy to implement.

- Low-Speed: Suitable for applications where high data transfer rates are not required.

- Point-to-Point or Multi-Drop: Can be used for single or multiple device connections.

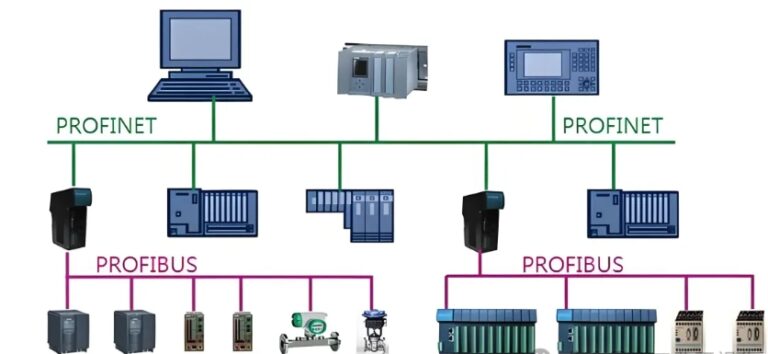

7. PROFIBUS Communication

PROFIBUS (Process Field Bus) is an industrial communication standard designed for high-speed data transfer between controllers and field devices. There are two main types of PROFIBUS: PROFIBUS-DP (Decentralized Peripherals) for fast communication between automation systems and sensors/actuators, and PROFIBUS-PA (Process Automation) for process automation applications in hazardous environments. PROFIBUS provides real-time communication and is used extensively in factory and process automation.

Key features:

- High-Speed Communication: Suitable for real-time control and monitoring.

- Two Types: PROFIBUS-DP for discrete automation and PROFIBUS-PA for process automation.

- Widely Adopted: Extensive use in various industrial sectors.

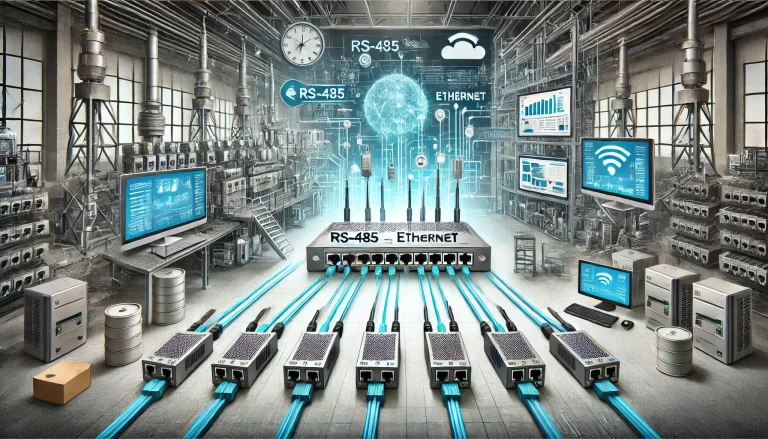

8. Industrial Ethernet

Industrial Ethernet is an adaptation of standard Ethernet for use in industrial environments. It is designed to handle the rigorous demands of industrial applications, including real-time data transfer, reliability, and robustness against electromagnetic interference. Industrial Ethernet allows for high-speed communication and integration with enterprise networks, making it ideal for complex automation systems that require large volumes of data transfer.

Key features:

- High-Speed: Can support up to gigabit speeds.

- Real-Time Capabilities: Enables precise control and monitoring.

- Enterprise Integration: Seamlessly integrates with corporate IT systems.

9. ASI (Actuator Sensor Interface)

ASI is a simple, low-cost protocol used for connecting sensors and actuators to controllers in automation systems. It’s primarily used for discrete manufacturing environments where cost-effective and simple communication is needed between devices. ASI reduces wiring complexity and is used in automotive manufacturing, packaging, and material handling systems.

Key features:

- Simple and Low-Cost: Ideal for connecting sensors and actuators.

- Simplified Wiring: Reduces the complexity of cabling.

- Discrete Manufacturing Focus: Used in areas like automotive and packaging.

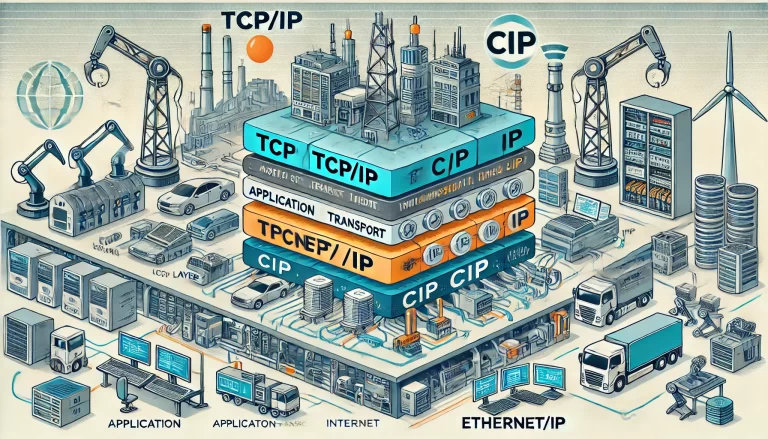

10. TCP/IP Protocol

TCP (Transmission Control Protocol) and UDP (User Datagram Protocol) are core protocols of the internet, but they are also used in industrial communication. TCP is a reliable, connection-based protocol that ensures data is delivered accurately, while UDP is a faster, connectionless protocol used when speed is more critical than reliability. Both are used in industrial Ethernet networks to transfer data between devices like controllers, sensors, and enterprise systems.

Key features:

- Reliable (TCP): Ensures accurate data delivery with error-checking mechanisms.

- Fast (UDP): Prioritizes speed over reliability in some real-time applications.

- Internet Integration: Supports seamless data transfer over local and global networks.

11. PROFINET Communication

PROFINET is an industrial communication protocol that builds on the capabilities of Ethernet, providing real-time data exchange and deterministic control in automation systems. It is designed for demanding applications, such as motion control, robotics, and process automation, where precise timing and reliability are critical.

Key features:

- Ethernet-Based: Combines Ethernet with real-time communication capabilities.

- Real-Time Communication: Supports deterministic control for fast processes.

- Scalability: Suitable for systems ranging from small automation cells to large industrial plants.

12. DeviceNet Communication

DeviceNet is a communication protocol based on the CAN (Controller Area Network) bus standard. It is widely used for connecting industrial devices like sensors and actuators to controllers, especially in factory automation. DeviceNet offers real-time data transfer and is particularly useful in situations where devices need to exchange small amounts of data frequently.

Key features:

- CAN-Based: Built on the reliable CAN bus architecture.

- Device-Level Communication: Used for connecting field devices in automation systems.

- Real-Time Capabilities: Supports real-time control applications.

Conclusion

Communication protocols in instrumentation vary in their complexity, speed, and range of applications. From traditional serial protocols like RS-232 and RS-485 to modern Ethernet-based solutions like PROFINET and industrial Ethernet, each protocol serves a unique role in ensuring efficient and reliable data exchange in industrial environments. Understanding the strengths and limitations of each protocol is crucial for selecting the right solution to meet the specific needs of automation, control, and monitoring systems.