Radar-based level measurement technologies, such as Radar Level Transmitters and Guided Wave Radar (GWR) Level Transmitters, are widely used in industrial settings for liquid and solid material level measurement. Despite both being radar technologies, they operate differently and are suited for various applications depending on the environment, measurement medium, and operational conditions. In this article, we will explore these two technologies in greater detail, highlighting their differences in terms of working principles, applications, accuracy, installation, and more.

1. Working Principle

Radar Level Transmitter (RLT): Radar Level Transmitters utilize a non-contact measurement technique based on the time-of-flight principle. High-frequency electromagnetic waves, typically in the microwave range, are emitted by the transmitter and directed toward the surface of the medium inside a vessel. The wave is reflected back to the sensor when it hits the surface of the medium. The transmitter measures the time difference between the emission and reception of the signal to calculate the distance from the sensor to the material surface, which is then converted into a level reading.

Guided Wave Radar Level Transmitter (GWR): Guided Wave Radar Level Transmitters, unlike traditional radar, use a contact measurement technique. They transmit electromagnetic pulses along a probe, such as a cable or rod, that is in contact with the medium. When the pulses reach the surface of the medium, a portion of the energy is reflected back along the probe. The time between the pulse emission and reception is used to calculate the liquid or solid level in the vessel. The guided probe helps focus the signal, making it ideal for challenging measurement conditions.

2. Measurement Medium

Radar Level Transmitter: Since radar level transmitters are non-contact devices, they can measure a wide range of media, including liquids, solids, slurries, and powders. Their ability to function without direct contact with the material makes them ideal for measuring aggressive, highly viscous, or abrasive materials that could damage or affect contact-type sensors.

Guided Wave Radar Level Transmitter: GWR is primarily used for liquid measurements but can also be applied to some solid materials. However, the performance may not be as stable as that of traditional radar for solid applications. GWR is more appropriate for environments where the medium is turbulent, foamy, or has fluctuating dielectric properties, as the guided probe ensures the radar signal reaches and returns from the material without significant interference.

3. Installation and Configuration

Radar Level Transmitter: Radar level transmitters offer flexibility in installation because they are non-contact devices. They can be mounted on the top of tanks, silos, or vessels without needing any direct interaction with the material. Since they don’t require immersion in the medium, they are less affected by material buildup, making them ideal for environments with minimal maintenance access. The absence of moving parts and lack of direct exposure to the medium make them robust and long-lasting.

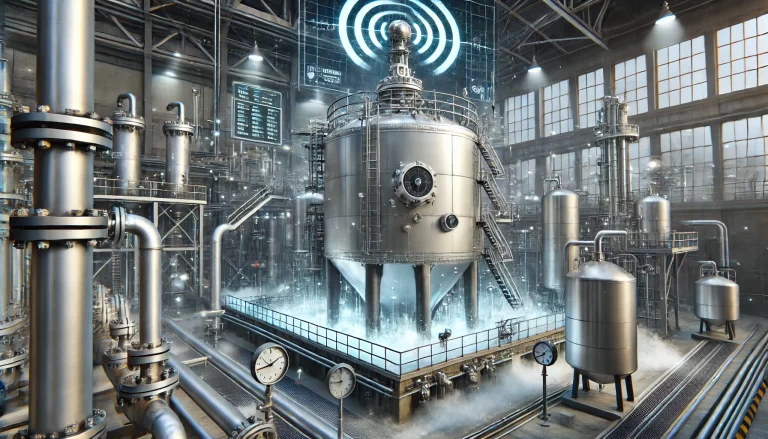

Guided Wave Radar Level Transmitter: GWR requires the installation of a probe inside the vessel, which means the setup is somewhat more complex than a non-contact radar system. The probe (rod or cable) must extend into the medium, so enough space must be allocated in the tank or vessel for the probe to be correctly positioned. This also means that GWR systems are more suitable for applications where internal vessel space is available and where the probe’s contact with the medium is beneficial for ensuring signal stability.

4. Accuracy and Reliability

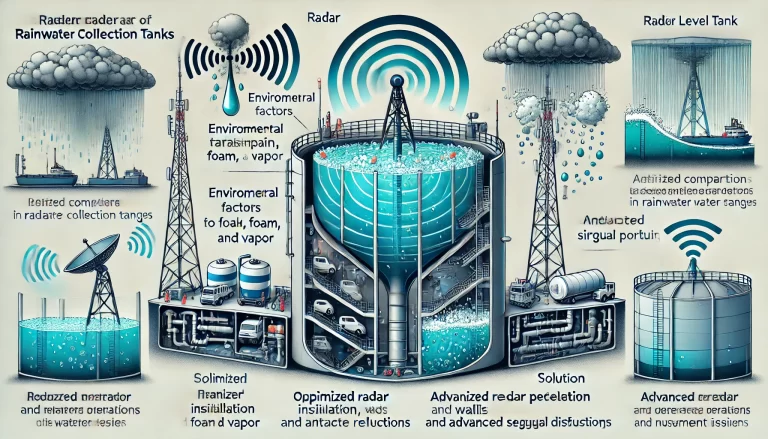

Radar Level Transmitter: Non-contact radar systems offer excellent accuracy and are widely used in environments where high precision is required. They are capable of measuring under various challenging conditions, including high temperatures, high pressures, and environments with corrosive or toxic materials. Moreover, since they don’t rely on physical contact, they are not affected by material buildup, ensuring consistent performance over time. Radar level transmitters are also effective in environments with significant dust, vapor, foam, or condensate, maintaining high accuracy even in such challenging settings.

Guided Wave Radar Level Transmitter: GWR transmitters also provide high accuracy, particularly in applications involving liquid measurement. Since the guided probe directs the electromagnetic pulses, they are less affected by foam, vapors, or turbulence at the liquid surface. This makes GWR ideal for applications where other radar systems may struggle to distinguish between the liquid and interfering elements, like foam or steam. However, because of the physical contact between the probe and the medium, buildup on the probe can affect performance in certain applications.

5. Environmental Suitability

Radar Level Transmitter: One of the key advantages of radar level transmitters is their versatility in extreme conditions. These devices can handle high temperatures, high pressure, and corrosive environments because of their non-contact design. For example, in environments where high-pressure vessels are used or where the media is volatile, a non-contact solution is preferred to avoid compromising the integrity of the sensor.

Guided Wave Radar Level Transmitter: GWR can also operate in challenging environments, including high-pressure and high-temperature applications. However, because the probe is in direct contact with the medium, it may require special materials to handle corrosive or highly abrasive media. GWR is especially effective in applications with low dielectric materials, where the guided wave can still maintain signal integrity despite the medium’s properties.

6. Cost and Maintenance

Radar Level Transmitter: Generally, radar level transmitters are more expensive than guided wave radar due to their more advanced sensing technology and non-contact design. However, they require less maintenance over time, as there are no components in direct contact with the material. This can reduce operational downtime and lead to long-term cost savings, especially in environments where accessing the sensor for cleaning or repairs is difficult.

Guided Wave Radar Level Transmitter: GWR devices are typically more affordable than non-contact radar level transmitters. However, since they rely on physical contact with the material, they may require periodic maintenance, particularly in applications where material buildup or scaling is a concern. The cost savings from the initial investment can be offset by the need for more frequent inspections and cleaning, depending on the medium being measured.

Conclusion:

Choosing between a Radar Level Transmitter and a Guided Wave Radar Level Transmitter depends on various factors, including the type of medium, environmental conditions, installation space, and budget considerations.

Radar Level Transmitters are ideal for non-contact applications where high accuracy and low maintenance are essential, especially in challenging or extreme environments such as high-temperature, high-pressure, or corrosive settings.

Guided Wave Radar Transmitters are well-suited for liquid measurements in turbulent, foamy, or low dielectric environments, providing high accuracy and signal stability due to their guided measurement approach.

In summary, the key differences between these two technologies come down to the contact or non-contact nature of the sensor, their ability to handle different materials, and their suitability for various industrial conditions. Each technology offers distinct advantages that make them suitable for specific applications, ensuring accurate and reliable level measurements.