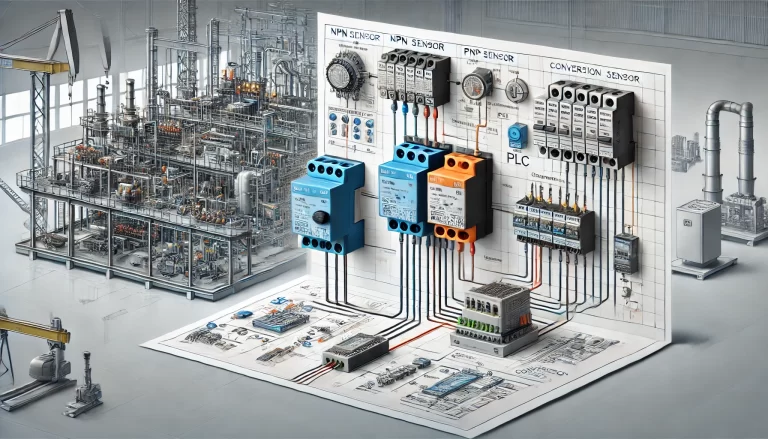

In industrial automation, the design of instrumentation and control systems relies heavily on the proper configuration of sensors, switching signals, and actuators. Among the commonly used interface types, PNP signal output and relay output are two prevalent options. This article will explore the differences between PNP and relay outputs in terms of their definition, working principles, application scenarios, advantages, and disadvantages, providing a comprehensive guide to selecting the right output type for specific needs.

1. Basic Definitions

1.1 PNP Output

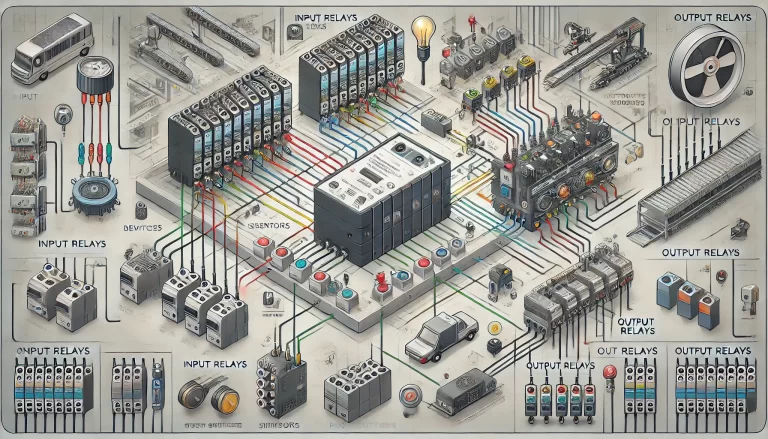

PNP output refers to a transistor output configuration where the signal output terminal is connected to a positive power source (typically +24V). In a PNP output system, when the sensor detects a signal, an internal PNP transistor connects the positive voltage, allowing current to flow from the output terminal to the load, and then return to the power supply’s common ground (typically 0V). This type of output is commonly known as “sourcing output” or “high-side switching.”

1.2 Relay Output

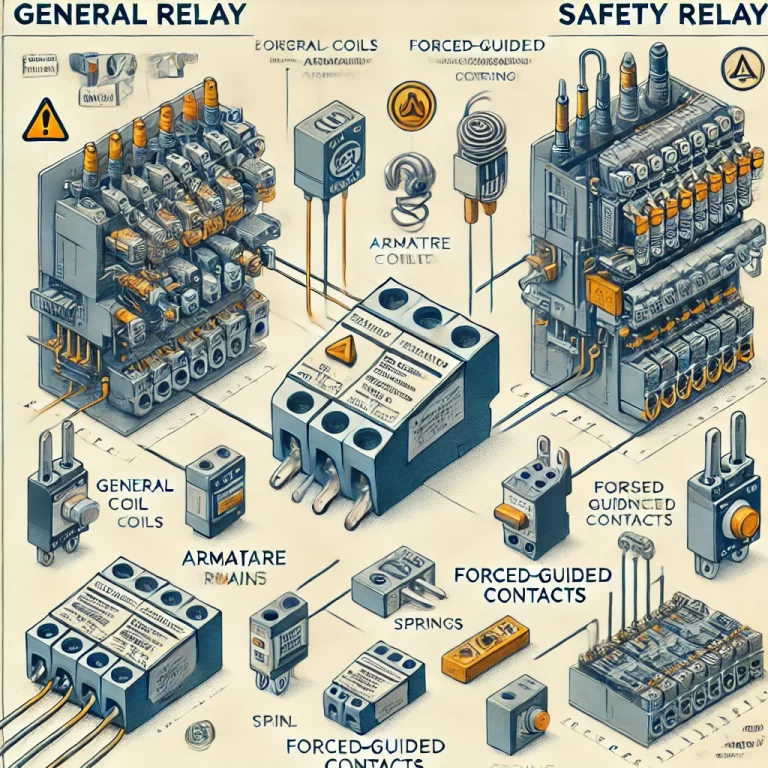

A relay is an electromechanical switch that operates by using an electromagnetic coil to open or close mechanical contacts when the input signal reaches a specified level. Relay output achieves circuit control through direct contact switching, and its operation is independent of the power source type. Common relay contact types include normally open (NO) and normally closed (NC) configurations.

2. Working Principles

2.1 PNP Output

Semiconductor-based Circuitry: PNP output relies on semiconductor technology, specifically PNP transistors.

Signal Flow: When the sensor detects an object, it outputs a positive voltage, causing current to flow from the output terminal through the load to ground.

No Mechanical Action: The entire switching process occurs electronically, ensuring high-speed response without moving parts.

2.2 Relay Output

Electromagnetic Operation: Relays work based on electromagnetic induction; when the coil is energized, it generates a magnetic field that moves the contacts.

Physical Contact Switching: The relay toggles between open and closed states, capable of handling high-voltage and high-current devices.

Mechanical Movement: As mechanical contacts are involved, response time is slower compared to semiconductor-based systems.

3. Application Scenarios

3.1 PNP Output Applications

PNP outputs are well-suited for low-voltage DC signals (e.g., 24V) and fast signal transmission applications, such as:

Conveyor belt monitoring: PNP sensors can provide precise positioning via photoelectric detection or proximity switches, transmitting signals to PLCs or microcontrollers for rapid processing.

Low-current control systems: Ideal for PLC input modules and microcontroller-based control systems.

High-speed automation systems: Frequently used in scenarios requiring fast and frequent switching operations.

3.2 Relay Output Applications

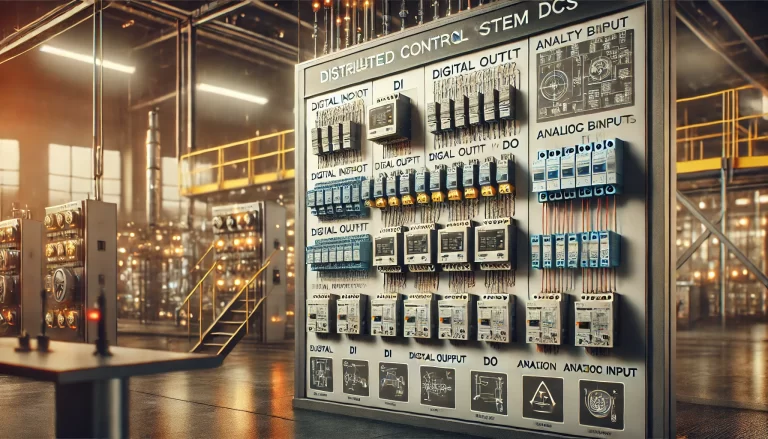

Relay outputs are preferred for controlling high-voltage or high-current loads, such as:

Industrial motor control: Relays are commonly used to switch high-power motors on and off.

Electrical isolation applications: Providing isolation between control circuits and high-voltage equipment to enhance safety.

Building automation: Widely used in lighting systems, HVAC controls, and safety interlock systems.

4. Advantages and Disadvantages Comparison

4.1 PNP Output

Advantages:

High-speed response: Fast switching makes it suitable for frequent operations.

No mechanical wear: As there are no moving parts, longevity is enhanced.

Compact size: PNP devices are smaller, facilitating integration into compact control systems.

Disadvantages:

Limited current capacity: Not suitable for driving high-power loads directly.

Polarity sensitivity: Requires careful attention to the correct wiring of power and ground connections.

4.2 Relay Output

Advantages:

High load capacity: Capable of directly switching high-power devices.

Electrical isolation: Provides effective separation between control and power circuits.

Versatile configurations: Available in NO, NC, and SPDT configurations for various control needs.

Disadvantages:

Slower response: Mechanical operation introduces latency (typically 10-50ms).

Mechanical wear: Contacts can degrade over time with repeated use.

Larger physical size: Requires more space and may be affected by environmental factors such as vibration.

5. How to Choose the Right Output Type

Selecting between PNP and relay outputs depends on several critical factors, including:

Load Characteristics:

For low-current digital signal applications, PNP output is preferred.

For high-current or high-voltage applications, relay output is the best choice.

Response Speed:

High-speed switching favors PNP output.

Slow-switching applications can use relay output.

Electrical Isolation:

Relay output offers superior isolation for safety-critical environments.

Reliability and Lifespan:

PNP output is ideal for frequent switching with a long lifespan.

Relay output requires periodic maintenance due to mechanical wear.

6. Conclusion

Both PNP and relay outputs serve crucial roles in industrial automation systems, each with distinct advantages tailored to specific applications. PNP outputs excel in low-voltage, high-speed scenarios with minimal wear, while relay outputs provide robust solutions for high-power applications with effective electrical isolation. Engineers should carefully consider load requirements, switching speed, and long-term reliability when choosing between these two output types.

By understanding the differences, advantages, and best use cases of PNP and relay outputs, automation professionals can make informed decisions to optimize system design and enhance operational efficiency.