Becoming a skilled instrumentation technician requires a blend of theoretical knowledge, practical experience, and a commitment to safety and precision. Below is a detailed guide on how to develop the skills and attributes necessary to excel in this field.

1. Foundational Knowledge and Theoretical Understanding

A strong base in core principles is essential for any instrumentation technician. Here are some crucial areas to focus on:

Electrical and Electronic Fundamentals: Understanding the basics of electrical circuits, voltage, current, and resistance is essential. Learn how to read and interpret circuit diagrams and schematics, as well as how various electronic components such as resistors, capacitors, and transistors function.

Principles of Automation and Control Systems: Gain a solid grasp of how automated control systems work, including the role of feedback loops, controllers, and sensors in maintaining system stability.

Measurement Techniques: Study the different types of measurement methods and instruments used for variables like temperature, pressure, flow, and level. This includes familiarizing yourself with devices like pressure gauges, thermocouples, flow meters, and level transmitters.

Engineering Drawings and Technical Documentation: Learn to read and create detailed technical drawings and flow diagrams, which are vital for understanding system layouts and troubleshooting issues.

2. Hands-On Practical Skills

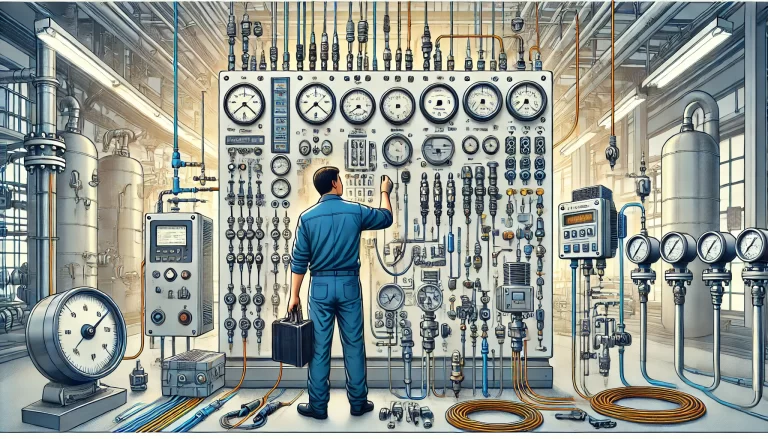

Practical skills are at the heart of an instrumentation technician’s role. You should develop the following competencies:

Installation and Commissioning: Understand the process of installing various instruments and sensors in different environments, from industrial plants to research facilities. Learn to connect these devices to control panels and ensure they function as expected.

Routine Maintenance and Troubleshooting: Practice identifying and resolving faults in instruments and control systems. This includes understanding how to use diagnostic tools and interpret signal outputs to pinpoint issues.

Calibration and Standardization: Become proficient in calibrating instruments to meet regulatory standards and ensure accurate measurements. This involves working with reference instruments and applying specific procedures to adjust devices.

3. Safety Standards and Best Practices

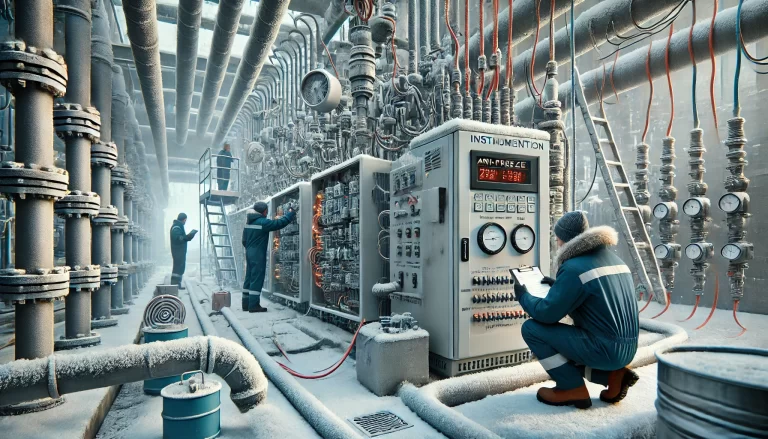

Adherence to safety protocols is paramount in any technical field, especially one involving electrical and mechanical systems.

Safety Training and Awareness: Regularly update your knowledge of safety regulations, especially when working in hazardous environments such as chemical plants or refineries. Understand and follow safety protocols related to high-voltage work, confined spaces, and hot work.

Explosion-Proof Equipment: Familiarize yourself with safety guidelines for working with and around explosion-proof equipment. This is particularly relevant in industries where flammable gases or vapors are present.

4. Proficiency in Technology and Software

Modern instrumentation relies heavily on technology, making software literacy an important skill.

PLC Programming: Learn how to program and configure programmable logic controllers (PLCs) used in automated systems. This includes writing ladder logic and using PLC software for diagnostics.

SCADA Systems: Develop the ability to work with supervisory control and data acquisition (SCADA) systems for monitoring and controlling industrial processes.

Data Analysis Tools: Be comfortable with data acquisition and analysis software to track instrument performance and interpret data trends for proactive maintenance.

5. Ongoing Learning and Professional Development

The field of instrumentation is ever-evolving, with new technologies and methods introduced regularly.

Stay Updated on Industry Trends: Regularly read industry publications and attend trade shows or workshops to keep up with advancements in smart instrumentation and wireless sensor technology.

Certification and Training Programs: Pursue certifications such as the Certified Control Systems Technician (CCST) or the Instrumentation Engineering Technology certification to validate your skills and knowledge.

Advanced Learning: Enroll in advanced courses or workshops that focus on specific instrumentation technologies, such as ultrasonic flow meters or advanced calibration techniques.

6. Developing Essential Personal Attributes

Beyond technical skills, certain personal qualities are crucial for success as an instrumentation technician:

Attention to Detail: The ability to work with precision is key when calibrating or installing instruments to avoid costly errors.

Problem-Solving Skills: Be adept at quickly analyzing situations and coming up with effective solutions when faced with complex issues.

Teamwork and Communication: Effective communication with other technicians, engineers, and team members ensures smooth project execution and troubleshooting.

Patience and Persistence: Troubleshooting can be time-consuming and challenging. Staying patient and persistent helps in maintaining efficiency and morale.

Conclusion

Becoming a proficient instrumentation technician involves more than just technical know-how. It requires a commitment to continuous learning, adherence to safety standards, and the development of practical and analytical skills. By focusing on these areas, you can build a successful and rewarding career in instrumentation technology.